Table of Content

Up to 70% of your heat will be lost through the roof and floor- therefore you must insulate these areas properly. A study carried out by the University of Maine, found that logs play a vital role in conserving energy. They absorb heat energy during the day and radiate it at night to maintain an even temperature. They did everything from scratch including felling their own trees, debarking them, and raising the walls.

Otherwise, try to choose a location that has mostly dry soil and large trees for shade. You might choose to build a log house as your vacation home, your beach house, or as your main living area. Once these logs are selected, they must be prepared for use in the construction of the home. The bark is removed from round logs with a two-handled drawknife.

Choose The Right Foundation For Your Log Cabin

Funding of the foundation, a floor system, electric, insulation, plumbing, a heating system, or any finish on the interior. It is determined by the number of logs in the kit and the mileage to your building site from our yard. All steps of the process are supervised by our experienced carpenters, log specialists, and designers. The end result is a log home that displays astonishing wood artistry and optimal organic living—as attested by our awards. Our experienced crew will reassemble the logs on your foundation/subfloor in a surprisingly short amount of time.

A handcrafted, full-scribe-fit log home that you cut yourself. All our home shells are full-scribe-fit and completely handmade. "Cut-It-Yourself" is the best way to build your own full-scribe-fit, handcrafted log home. Turned logs are normally cut from a whole tree, using giant lathes or milling machines to turn the log to a uniform diameter. Three sides are cut flat and the fourth shaped to one of several different exterior designs. No need to settle for the frustration and the potential disappointment packed into a cabin kit along with its materials.

Can You Build A Log Cabin Kit By Yourself?

Using uniform logs also saves construction time, and makes installation of interior woodwork much easier. Photo courtesy of Gastineau Log HomesWhen purchasing a manufactured log home kit, make absolutely sure you understand exactly what will be furnished and how. In most instances you will be purchasing a building from a photo or drawing and a floor plan. All materials for log porches and balconies should be included if they are in the plans for the home.

They are the source of its energy efficiency, strength and beauty. Wall logs come in many shapes and sizes and many different techniques are used to join them. Installing Door Jambs.Door jambs must also be positioned in the wall as the first course of logs is being installed. The door itself is generally removed and only the frame remains in place.

Are Log Cabin Kits Worth It

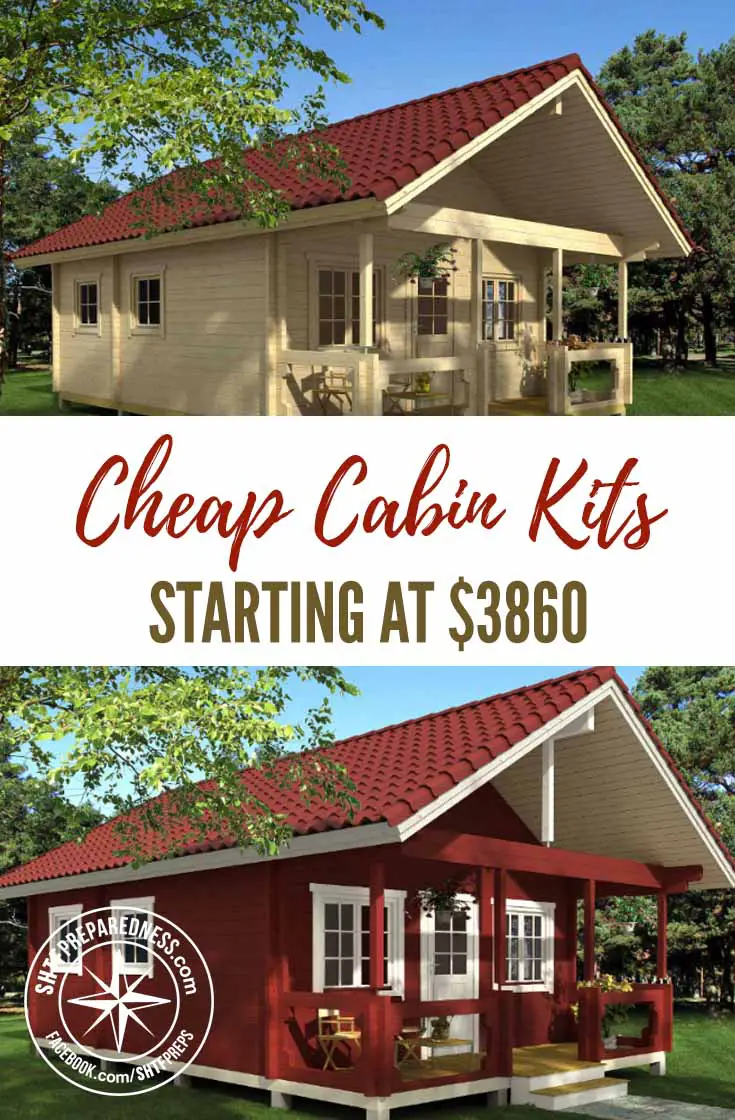

Think of porches, wraparound porches, balconies, floors, and different roof styles that can differentiate your log home and add character and personality. My Google search brought me to this log cabin kit named The Gatlinburg, instead. Build Your Log Cabin with a kit from Log Cabins for LessThe kits are available two different ways. You can buy a kit with just the logs or a kit with everything you need to completely build a new log home. They also sell materials like big beam and timber roof systems, log tongue and groove siding, knotty pine doors and log porch and stair railings. When you buy from a kit company, the relationship ends when the material shows up.

The next step, involving more work but a great deal less cost, is to purchase a “kit” log home and erect it yourself. For instance you can purchase only milled or debarked logs if you wish to cut your own notches, window and door openings. You can also purchase a kit consisting of only the walls, along with spikes, gaskets and other items needed. Another type is the “shell” kit, which includes the walls, roof and floor framing, and sometimes the windows and doors.

Exterior Finish

A modular log home, on the other hand, allows its owner to participate in the construction process as much as they want. The best part of modular construction is that most of the hard work is done. A modular log home requires assembly, but it isn’t the ground up construction process that log home kits require. This is quick and easy to build and again, no under cup or groove is used.

It surprises many people to learn that the type of soil under the home is more of a factor in determining the size and type of footings and foundation than the weight of the home. Make the most of your planning and preparation period and find out as much as you can before building a log home. Sticking to a regular maintenance schedule is far more effective and cheaper than irregular repair and fixes. Regular maintenance of your log cabin reduces the damage from UV, water, insects, and air infiltration. You may think that logs are inferior to conventional buildings, however, logs have an added benefit, they act like thermal batteries.

Prime coats will be applied to the walls first, followed by topcoats. The exterior finish includes graining, topsoil spreading, and landscape preparation. When you first start building a log home, you may be intimidated. However, once you’ve mastered the sequence of events, you’ll find the procedure less intimidating. Log homes are typically built with wells in order to dispose of waste, as well as water and septic systems.

You cut the corner notches and grooves of a full-scribe-fit log home shell that has already been completely scribed by my staff of professional log builders. Photo courtesy of Gastineau Log HomesDepending on the kit, the logs may or may not be treated against decay and insect infestation. A variety of preservatives are available these days, such as Perma-Chink () clear coatings, that are environmentally friendly, clean and easy to apply. These are typically applied to the exterior after the logs are erected. Some are also applied to the interior to maintain the color of the logs and add to the décor. A corner notch is also fairly simple, but is more commonly used in post-and-beam or when several materials and styles are used in one building.

Then, lay down the 2 notched logs on the foundation with the 2 un-notched logs on top in a square shape. You’ll need a perfectly level foundation to start your log house on, so get to digging! If there’s vegetation and rocks in the way, this process could take up to a week. If you have to level out a hillside or a slope, it could take much longer.

One method of corner notch is to cut a slot in the corner logs and then cut a notch in the end of the adjoining logs and use a spline. The simplest and most expensive method is to purchase a manufactured log home and have it erected by the log home manufacturer. The logs in these buildings are normally milled to precise shapes to ensure tight, secure buildings. These are usually “one-of-a-kind” homes built to the purchaser’s designs.

This notch is more commonly used by custom log builders, rather than in kits. In this case the logs are not scribed on their bottoms, but fit full with milled joints or splines. This makes it somewhat easier to do and is a common kit-home style. This consists of a notch on top and one on the bottom of the crossing logs. This also alleviates the need for cutting the bottom cup or groove, but produces a much weaker corner joint. Log cabin kits are billed as a way for anyone to enjoy the log home lifestyle for a fraction of the price.

No comments:

Post a Comment